Silicone Applications

Versatile Solutions for Various Industries and Applications

Unlock the potential of 3D printing to elevate your business.

Explore 3D Printing Solutions

Innovative Applications

Explore the endless possibilities of silicone 3D printing across various industries.

Pneumatic Grippers

Silicone 3D Printing

San Draw’s SIL18 silicone grippers are made from ultra-soft Shore A 18 silicone, offering an excellent balance of precision, flexibility, and adaptability. The inherent softness of SIL18 allows the grippers to conform to delicate or irregular objects, ensuring secure handling without causing damage. Enabled by high-precision silicone 3D printing technology, these grippers combine accurate geometry with durable material performance, delivering reliable and repeatable results for automation, soft robotics, and research applications.

Lattice Structure

Silicone 3D Printing

Creating silicone lattice structures with traditional methods is extremely difficult due to stacking limitations and the complexity of removing support materials. With San Draw silicone 3D printing technology, intricate lattice geometries can be produced with high precision and stability. Combined with our SP65 water-soluble support material, even the most complex silicone lattice structures can be printed cleanly, enabling new possibilities in bioengineering, soft robotics, and advanced product design.

Bellows

Silicone 3D Printing

Silicone bellows play a critical role in applications requiring flexibility, airtight sealing, and fatigue resistance. Traditional manufacturing methods struggle with complex geometries, limiting design freedom and performance. With San Draw silicone 3D printing technology, bellows can be produced in customized shapes with precise wall thickness and consistent durability. This capability enables advanced solutions for fluid control, flexible joints, and protective housings in research, engineering, and industrial applications.

Dental Training Model

Silicone 3D Printing

The silicone dental training model is engineered for realistic oral anatomy simulation. Using San Draw silicone 3D printing technology, the retainer and tongue base are produced separately with different silicone hardness levels and then bonded to ensure greater accuracy and durability. Made from ISO 10993-certified biocompatible silicone, this multi-material design provides a lifelike experience, making the model an excellent tool for dental education, research, and practical training.

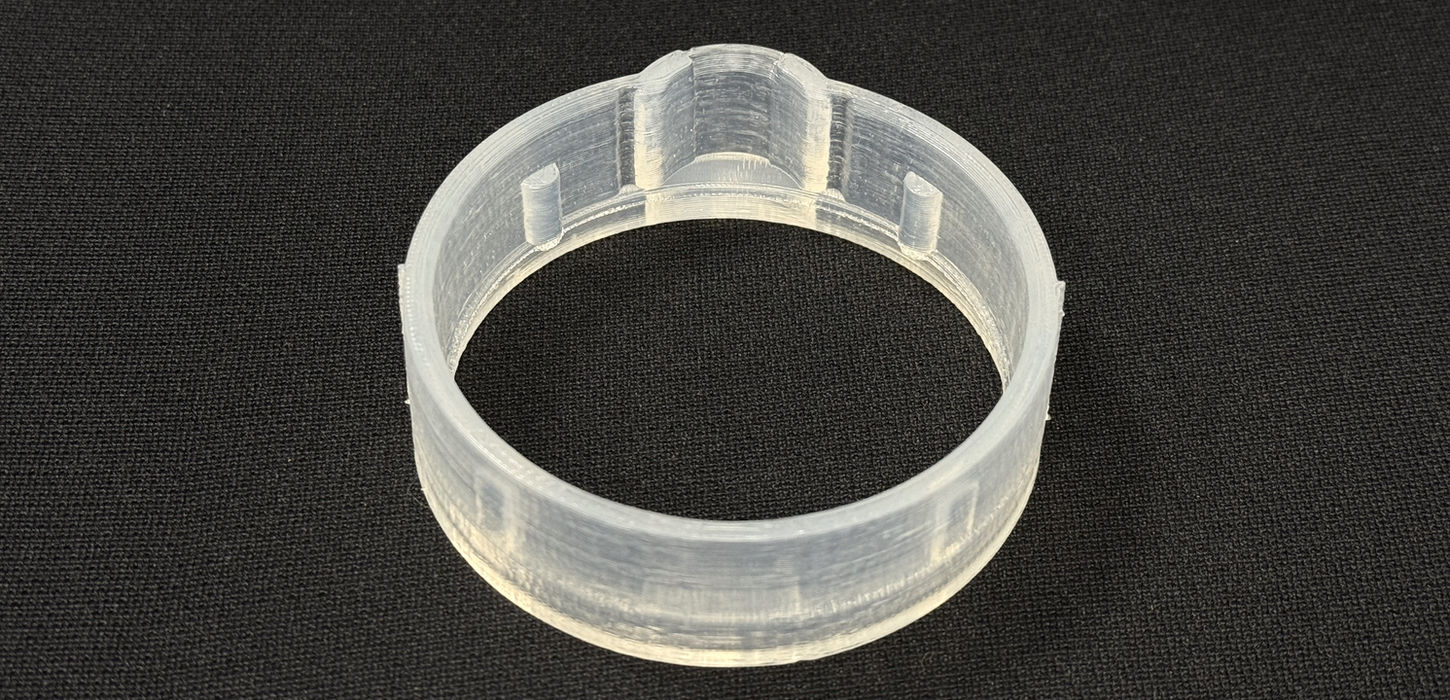

Fan Covers

Silicone 3D Printing

Silicone fan covers offer flexible protection and effective vibration damping for fans and sensitive components.

Using San Draw silicone 3D printing technology, these covers can be precisely produced with customized shapes and varying silicone hardness levels, ensuring both durability and elasticity.

This approach allows for efficient airflow management, impact absorption, and safe handling in applications such as electronics, robotics, and industrial equipment.

Irregular Vascular Structures

Silicone 3D Printing

Silicone irregular vascular structures are difficult to fabricate due to complex branching and fine apertures. With San Draw silicone 3D printing, these structures can be printed accurately and stably, using different silicone hardness levels if needed. Our SP65 water-soluble support material allows for easy removal, even in delicate areas. Made from ISO 10993-certified biocompatible silicone, these models are ideal for bioengineering research, educational training, and experimental prototyping.

Explore More Applications

Medical Parts

Engineering Parts

Robot Parts

Bioengineering

Silicone Mold

Dental Appliance

Baby Care Product

Aerospace Parts

Other Applications

.png)