About San Draw

Founded in Silicon Valley in 2014, San Draw established its headquarters in Taiwan in 2015, specializing in the development and application of advanced silicone 3D printing technology.

By combining the entrepreneurial innovation of Silicon Valley with Taiwan’s exceptional engineering talent, San Draw has built a technology-driven company with a highly skilled and dynamic team.

Our expertise and innovative approach enable the creation of precise, high-quality silicone 3D printed products, serving industries that demand performance, flexibility, and reliability.

FAM – Fluid Additive Manufacturing

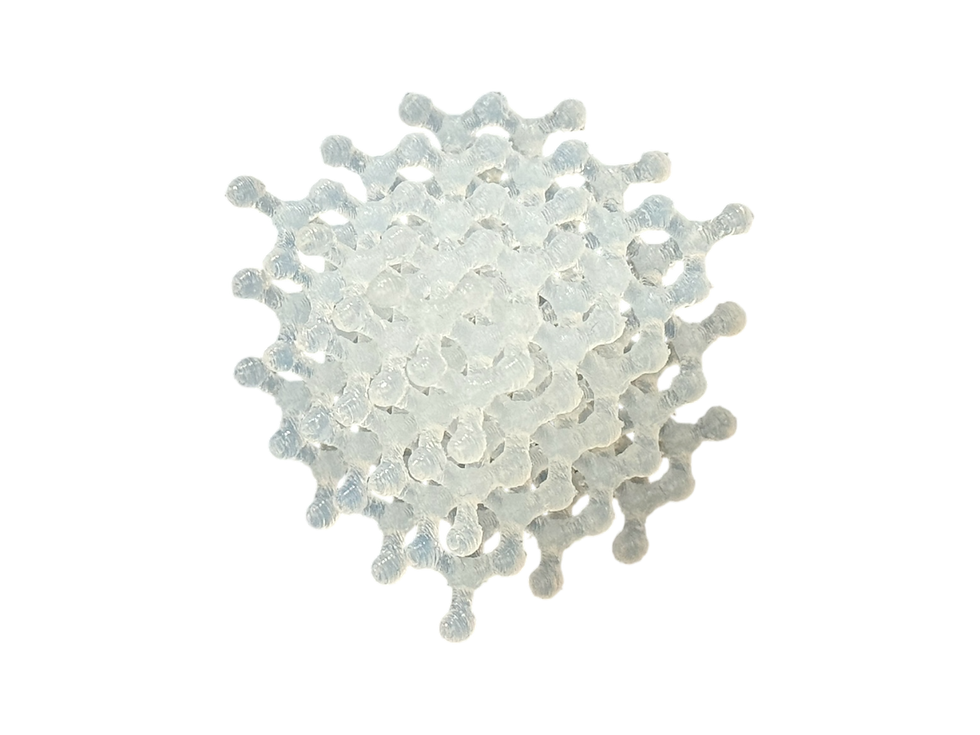

Our patented FAM (Fluid Additive Manufacturing) technology is the world’s first advanced silicone 3D printing platform, specifically developed for RTV and LSR silicones.

All San Draw printers are equipped with FAM technology and our proprietary FAMufacture software, enabling precise, high-quality printing and seamless control over complex silicone applications.

San Draw 100% Pure Silicone

San Draw’s 100% pure silicone, specifically formulated for 3D printing, delivers outstanding flexibility, durability, and elasticity compared to standard commercial silicones.

This high-performance material ensures precise, reliable, and

long-lasting results for complex silicone 3D printing applications, making it ideal for advanced prototyping and customized production.

The company established its headquarters in Taiwan,

laying the foundation for continued research and global market expansion.

S052 and S200 silicone 3D printers were officially launched, marking an important step in scaling silicone 3D printing solutions.

That same year, the company participated in the Taiwan 3D Printing and Additive Manufacturing Show, strengthening its industry presence.

The company released S053 and S300 silicone 3D printers.

In parallel, San Draw developed a proprietary water-soluble support material designed for two-part silicone printing,

solving long-standing challenges in fabricating complex geometries.

The year also included another participation in the Taiwan 3D Printing and Additive Manufacturing Show.

S400 silicone 3D printer was launched, featuring the capability to simultaneously print two sets of two-part silicone or water-soluble supports, enabling new levels of design complexity.

San Draw presented its latest solutions at the Taiwan 3D Printing and Additive Manufacturing Show, highlighting advancements in elastomer additive manufacturing.

Key milestones in two-part silicone 3D printing and water-soluble support development

Our Journey in Silicone 3D Printing

2015

2020

2022

2024

2014

San Draw introduced FAM technology, recognized as the world’s first commercially available silicone 3D printing process.

This innovation opened new possibilities for additive manufacturing with real silicone materials.

2017

San Draw showcased its silicone 3D printing technology for the first time at the Taiwan International 3D Printing Show, bringing attention to the future of additive manufacturing with elastomers.

2021

San Draw exhibited at Touch Taiwan – Smart Manufacturing Taiwan and returned to the Taiwan 3D Printing and Additive Manufacturing Show, further promoting the potential of silicone 3D printing in advanced manufacturing.

2023

San Draw introduced S180 silicone 3D printer, designed to meet growing demand for precision and material flexibility.

The company also showcased its innovations again at the Taiwan 3D Printing and Additive Manufacturing Show.

2025

San Draw continues to demonstrate leadership in the industry by participating in the Taiwan 3D Printing and Additive Manufacturing Show, reinforcing its role as a pioneer in silicone 3D printing technologies.

.png)