Advancing Medical Training and Research with Silicone 3D Printing: Realistic Heart Models with Water-Soluble Support Materials

- Oct 31

- 3 min read

Bridging Technology and Medical Training

As medical research and education continue to advance, the demand for realistic anatomical models has never been greater. Traditional resin-based 3D printing often fails to capture the flexibility, elasticity, and tactile feedback of real human tissue — elements that are essential for surgical training and device validation. Silicone 3D printing is reshaping how medical professionals and researchers replicate soft tissues. With San Draw’s professional-grade silicone 3D printing technology, medical training and research are entering a new era of precision and realism.

Challenges in Creating Realistic Medical Models!

Developing accurate and functional anatomical models is a long-standing challenge. Common materials like PLA or resin are rigid, brittle, and visually opaque, which limits their application in surgical simulation or interventional device testing. Moreover, internal vascular or cardiac structures — such as chambers and branching vessels — are nearly impossible to replicate with traditional manufacturing methods. Even with advanced 3D printing, removing internal supports without damaging the model has been a major obstacle.

How Silicone 3D Printing Solves These Problems?

San Draw’s silicone 3D printing system provides a groundbreaking solution. Using medical-grade silicone certified under ISO 10993, it reproduces soft, elastic, and biocompatible models ideal for research and simulation. What makes this technology stand out is its ability to print dual materials simultaneously: the main structure made of silicone, and a water-soluble support material that stabilizes complex internal geometries during the printing process. Once printing is complete, the support can be dissolved effortlessly with water, leaving behind clear, intact internal channels and cavities.

Demonstration: From Printing to Cleaning

After printing, the heart model is immersed in water, and the support material dissolves within seconds, revealing smooth, precise internal structures.

(Demonstration video)

Due to the heart’s complex internal structure, areas that are difficult to rinse directly can be easily cleaned by immersing the model in water, allowing the support material to dissolve easily.

During printing, each layer of silicone and support material is precisely deposited to replicate intricate organ features.

Applications in Medical Education and Research

Silicone 3D printing opens new opportunities for medical training, device testing, and anatomical research.

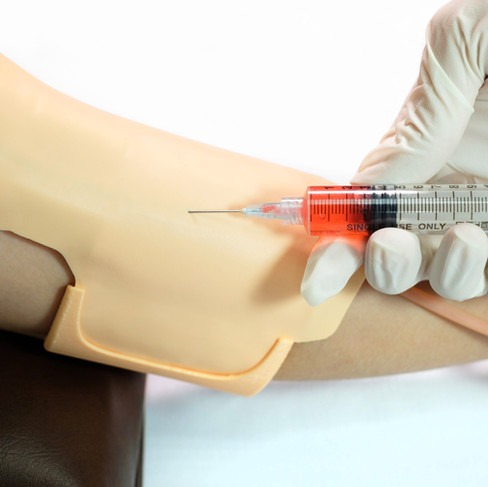

Medical Education: Enables students to practice procedures on highly realistic models that mimic real tissue behavior.

Device Development: Assists researchers in testing catheters, stents, or implantable sensors under near-real physiological conditions.

Customized Research Models: Facilitates tailored organ models for specific patient anatomy or experimental setups.

By combining elasticity, transparency, and fine detail, silicone models deliver an unprecedented level of anatomical accuracy and interactivity.

Value for Researchers and Developers

For many research teams, traditional manufacturing constraints can slow down iteration and validation. San Draw’s technology eliminates these barriers by enabling direct fabrication of functional prototypes that are mechanically and visually true to life. Researchers can submit their CAD files for free evaluation, receive printing samples, and assess the suitability of silicone 3D printing for their projects. This streamlined process accelerates innovation in both academia and the medical device industry.

Conclusion

Silicone 3D printing with water-soluble support materials provides practical and powerful solutions for those facing challenges in creating realistic anatomical models. It not only bridges the gap between engineering and medicine but also empowers researchers and educators to explore new possibilities in simulation and device development.

To see the process in action, watch the demonstration video or contact San Draw to request a free sample evaluation and learn how this technology can enhance your next research or training project.

Comments